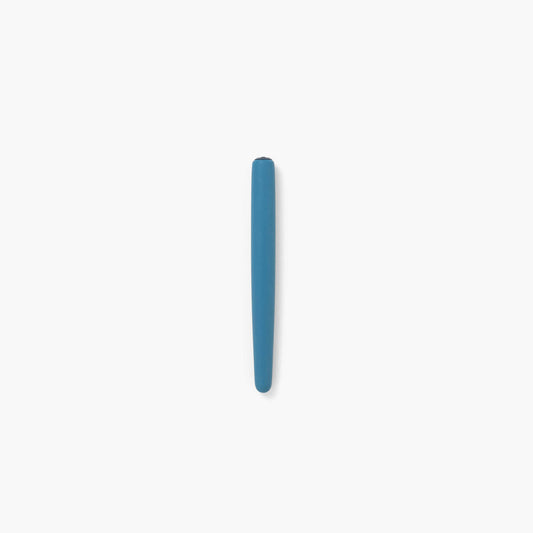

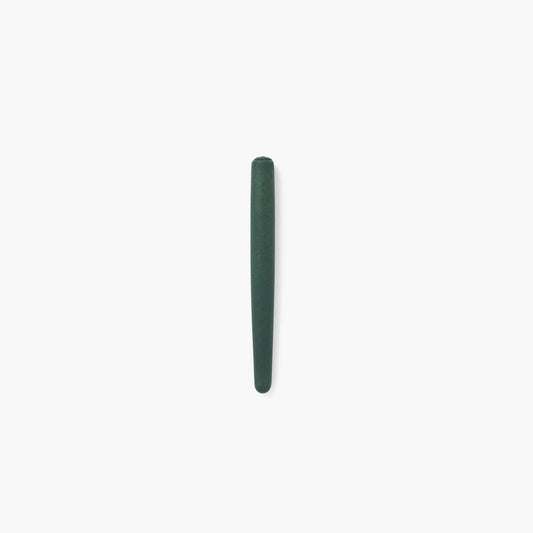

Kakimori first launched our own dip pens in the 2021 collection, New Tools for Writing with Joy. Since then, our dip pens have been embraced not only across Japan, but by writers all around the world.

We began as a small stationery shop, before gradually moving into designing our own products — continually exploring what kind of tools become treasured companions. Over the past four years, this journey has also inspired us to refine and improve the tools we’ve brought to life.

It was this process that led us to develop a nib mount for our dip pen holders.

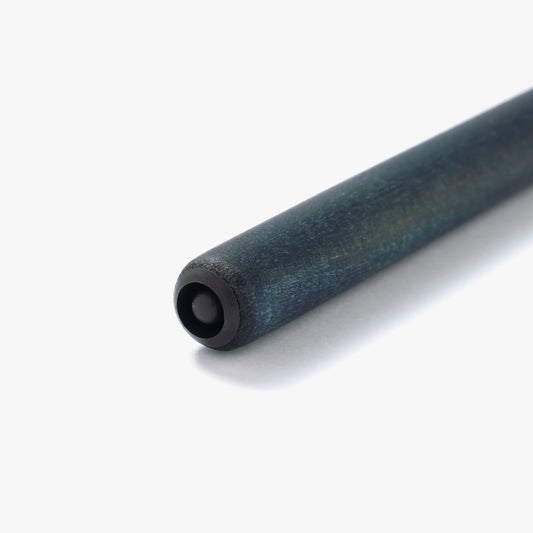

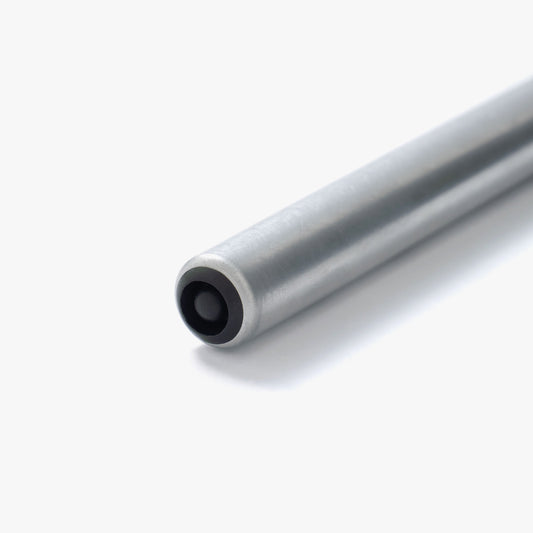

The nib mount is an integral part of the holder, keeping the nib securely in place while writing — the heart of the pen in many ways. Until now, we had used a ready-made component, but felt that there was room for improvement in its design, durability and grip.

It was around this time that we were introduced to Sakuma Special Steel and their new carbon fibre-based material, ReMax Composite®. A recycled carbon fibre composite, this specialised resin was developed through a partnership between Sakuma Special Steel and Furuta Kasei, a plastics manufacturer specialising in injection moulding.

Image by Sakuma Special Steel

Founded in 1973, Sakuma Special Steel is a company specialising in the design, development and sale of products ranging from automotive parts to tuning pins for grand pianos, servicing the global market. They are committed to delivering innovative solutions to challenges including material recycling, circular manufacturing and the revitalisation of regional industries.

Also founded in 1973, Furuta Kasei is an established contract plastics manufacturer with a reputation for high-precision production. They manufacture a wide range of products, including utility poles, automotive parts, knife handles and screws. More recently, they have launched a tableware brand featuring materials developed in-house.

Our nib mount is made from ReMax Composite®, a composite material combining recycled carbon fibre and resin. Originally developed for mechanical components such as bolts and screws, its resistance to rust and excellent durability also proved to be ideal properties for a nib mount.

This was our first time creating a custom nib mount. Our product development team worked closely with Sakuma Special Steel to design the mount from scratch, taking into consideration optimal grip and compatibility with not only Kakimori nibs, but with as many nibs from other brands as possible. The mould was produced through a high-precision process that carefully accounts for the shrinkage that occurs as resin cools.

Using this mould, the team at Furuta Kasei injection-moulded and finished the nib mount with skilled expertise. The result offers a superior grip and durability compared to standard components. Its ink-black colour reflects Kakimori’s aesthetic and harmonises effortlessly with any material. Thanks to this small, unassuming component, our dip pen holders can now be enjoyed for many more years to come.

While plastic resin is less favoured today largely due to sustainability concerns, Nobuyuki Furuta, who heads Furuta Kasei, explains that resin is ‘like a living organism’ — sensitive to temperature and humidity — and working with it requires the skill and sensitivity of the human hand, much like traditional craftsmanship.

Resin offers longevity when used thoughtfully and not as a disposable material. Even in industrial manufacturing, the presence of the human hand remains essential. This project gave us a renewed appreciation for the inimitable depth and quality of Japanese manufacturing.

Born from a collaboration with Sakuma Special Steel and Furuta Kasei, our nib mount is now part of our dip pen holders. We hope more writers will share in the joy of writing with our newly improved tools.

![ずっとそばにいる道具を、[br/pc]全国の仲間と、山桜の木で[br/pc]第一回](http://kakimori.com/cdn/shop/articles/12.jpg?v=1760603283&width=533)